Keep me updated

PemkoPrene Seal Adhesive Gasketing

Product Code: PK33_ & PK55_

PemkoPrene Seal Adhesive Gasketing

About Adhesive Gasketing (AG)

We offer a variety of adhesive-backed smoke and fire gasketing and edge sealing systems, including SiliconSeal, PemkoPrene, Silicone Triple-fin Gasketing and Hot Smoke Seal intumescent edge sealing for combination fire and smoke gasketing. Pemko gasketing is tested for sound resistence, smoke and draft control, fire rating, positive pressure, airworthiness and is BHMA certified.

About Adhesive-Backed Fire/Smoke Gasketing

Adhesive backed material installs easily to door frame.- All adhesive gaskets have a limited shelf life. These products must be used within 6 months of purchase and must be stored between 50 degrees (F) and 100 degrees (F).

- Thoroughly clean the frame with the enclosed cleansing towelette to remove grease, dust or cleanser build-up. Before installation, wait for frame surface to completely dry (evaporate). Some hospital environments have wax or anti-bacterial cleanser build-up. As an alternative or substitute cleanser, use isopropyl (rubbing) alcohol. Note: Mineral spirits or other petroleum based cleaning products should NOT be used.

- If frames are too cold (below 50ºF) or too hot (above 100ºF) adhesion may be impaired.

- Installation should take place after construction is completed, flooring is installed and final cleaning is completed.

- Paint on frame must be cured for at least 5-7 days. Paint cannot be wet under dry surface when gaskets are pressed on. Avoid quick-dry primers, which leave a powdery surface preventing sufficient adhesion. When applying to a wood frame, the surface must be non-porous and sealed. Follow standard industry guidelines on sealed wood frames and/or rough surface before applying. Note: Anti-bacterial, anti-fungal or silicone additives in paint may inhibit adhesion.

- Do NOT stretch material. Product can retract or shrink if stretched.

- Use very firm, perpendicular pressure when applying. Use wallpaper seam roller to reinforce adhesion after applying.

- Do not stretch material when using seam roller. Run roller with up and down motions.

- Double check adhesion after 2-3 hours before leaving job overnight.

- If gaskets separate from the frame, press again with firm pressure in place. If adhesive strip is exposed, airborne dust may impede adhesion. Replacement may be necessary.

- Application at header can be awkward due to overhead condition. Be sure to apply enough pressure.

- Adhesion takes delayed set. Immediate removal and resetting can be done if error occurs in initial placement. DO NOT reset after one hour. Full set is reached in 24 hours.

- SiliconSeal is extruded from high-temperature silicone; effective between -58°F and 450°F

- Self-extinguishing and non-toxic; unaffected by sunlight, ozone, and ultraviolet rays

- Impervious to fungus and mildew; will not deteriorate under normal exposure

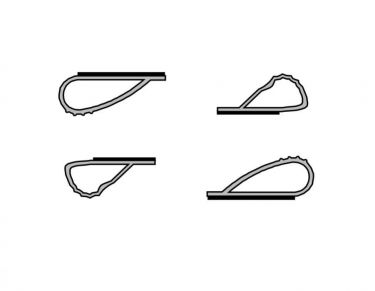

PK33_

AVAILABLE FINISHES: BL, D, W

AVAILABLE LENGTHS: 17', 18', 20', 21', 25', 30', 510'

Designed for tighter framesDemonstrates extremely low closing force

Seal begins compressing at 4.76mm; compresses to seal up to a 1.58mm gap

PK55_

AVAILABLE FINISHES: BL, D, W

AVAILABLE LENGTHS: 17', 18', 20', 21', 25', 30', 510’

Designed for tighter frames

Demonstrates extremely low closing force

Seal begins compressing at 4.76mm; compresses to seal up to a 1.58mm gap